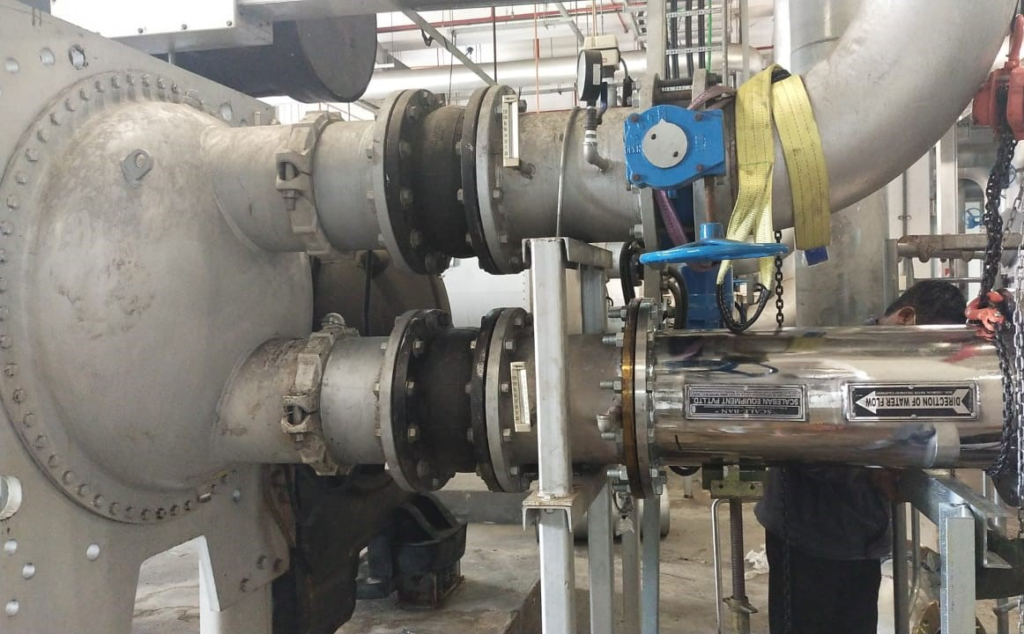

At SCALEBAN Equipment Pvt. Ltd., our primary objective is to safeguard our society and future generations by preserving our valuable natural resources – WATER and ENERGY. Our cutting-edge technology has enabled our clients to achieve significant water conservation and cost-effective Zero Liquid Discharge solutions. We take immense pride in the fact that our product, SCALEBAN not only facilitates ZLD across diverse industrial sectors but also contributes to the conservation of a substantial amount of water worldwide. Our core philosophy of “CONSERVE…PRESERVE…SERVE” is embodied by the SCALEBAN, which fulfills our desire to provide continuous service to humanity and society.

Water treatment plants are vital to ensuring that people have access to clean and safe drinking water. The process of treating water involves the use of various technologies to remove contaminants and impurities from the water. In this guide, we will explore the fascinating technology behind water treatment plants.

- Screening and Pre-Treatment

The first step in water treatment is screening and pre-treatment. This involves the use of screens to remove large debris and objects such as leaves, branches, and rocks. Once the larger debris has been removed, the water is treated with chemicals to remove smaller particles and impurities.

- Coagulation and Flocculation

After pre-treatment, coagulation and flocculation are used to remove smaller particles from the water. Coagulation involves the use of chemicals to cause small particles to clump together, forming larger particles called flocs. Flocculation then agitates the water to allow these flocs to come together and settle out of the water.

- Sedimentation

Once the flocs have settled out of the water, the water is ready for sedimentation. In this process, the water is allowed to sit still in large tanks, allowing any remaining particles and flocs to settle to the bottom of the tank. The clean water is then removed from the top of the tank.

- Filtration

After sedimentation, the water undergoes filtration to remove any remaining particles and impurities. This can be done using various types of filters, including sand filters, activated carbon filters, and reverse osmosis filters.

- Disinfection

The final step in water treatment systems is disinfection. This is done to kill any remaining bacteria, viruses, and other microorganisms in the water. This is typically done using chemicals such as chlorine, or by exposing the water to ultraviolet light.

In addition to these core processes, modern water treatment plants often use additional technologies to improve water quality and efficiency. Some of these technologies include:

- Membrane Filtration

Membrane filtration involves the use of semi-permeable membranes to remove impurities from the water. This technology is commonly used in reverse osmosis and nanofiltration systems. In comparison to Membrane filtration, Zero Liquid Discharge (ZLD) water treatment is more effective than Membrane Filtration because ZLD removes all contaminants and impurities, leaving no liquid waste, while Membrane Filtration only removes some contaminants and produces waste. ZLD is also more cost-effective in the long term due to reduced waste disposal costs.

- Ozonation

Ozonation involves the use of ozone gas to disinfect water. This technology is more effective at killing certain types of microorganisms than traditional disinfection methods such as chlorine.

- Ion Exchange

Ion exchange involves the use of resin beads to remove minerals and other impurities from the water. This technology is commonly used to soften hard water. While this technique is effective at removing certain contaminants from water, it also has some drawbacks. Here are a few; High costs, Waste disposal, Water quality issues & Environmental impact. In comparison to Ion Exchange, Zero Liquid Discharge (ZLD) is considered better than Ion Exchange (IX) because ZLD systems can completely eliminate wastewater discharge while IX systems only exchange ions and require additional treatment steps for discharge. ZLD also reduces environmental impact and improves water conservation.

- Activated Carbon Adsorption

Activated carbon adsorption involves the use of activated carbon to remove organic compounds and other impurities from the water. This technology is commonly used in drinking water treatment and wastewater treatment.

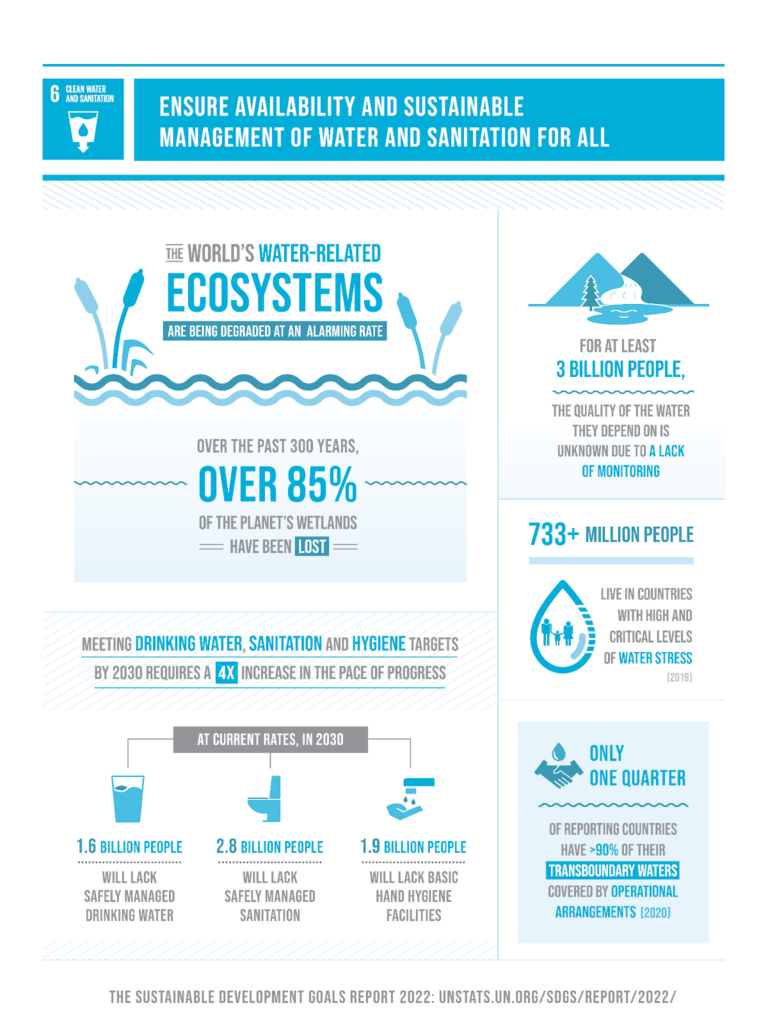

For years, the United Nations has been tackling the global crisis stemming from insufficient water supply to meet basic human needs, as well as the increasing demands on the world’s water resources to cater to human, commercial, and agricultural requirements. Several key events, such as the United Nations Water Conference in 1977, the International Drinking Water Supply and Sanitation Decade from 1981 to 1990, the International Conference on Water and the Environment in 1992, and the Earth Summit in the same year, have all been dedicated to addressing this crucial issue.

With Sustainable Development Goal 6, the focus is not limited to access to drinking water, sanitation, and hygiene. The goal also encompasses the quality and sustainability of water resources, which are vital for both people’s and the planet’s survival. The 2030 Agenda recognizes that water resources are central to sustainable development and acknowledges the essential role of improved drinking water, sanitation, and hygiene in promoting progress in other areas, such as health, education, and poverty reduction.

In conclusion, water treatment plants use a variety of technologies to ensure that people have access to clean and safe drinking water. From screening and pre-treatment to disinfection and additional technologies such as membrane filtration and ozonation, each step in the water treatment plants process plays a vital role in ensuring the safety and quality of our drinking water. As water becomes an increasingly scarce resource, the technology behind water treatment plants will continue to evolve and improve, ensuring that we can continue to meet our growing demand for clean water.