In recent years, the issue of industrial wastewater management has become an increasingly pressing concern for businesses across a wide range of industries. Traditional wastewater treatment methods can be expensive, time-consuming, and often result in the release of pollutants into the environment. As a result, many businesses are turning to innovative solutions like zero liquid discharge systems in India to address these challenges.

What is Zero Liquid Discharge?

Zero liquid discharge in India is a wastewater treatment process that aims to eliminate the discharge of any liquid effluent into the environment. Instead of releasing wastewater into nearby bodies of water or sewer systems, this system collects and treats the wastewater on-site, resulting in the production of dry solids and clean water that can be reused or recycled.

Zero liquid discharge system work by using a combination of physical, chemical, and biological treatment methods to remove contaminants from the wastewater. The treated wastewater is then evaporated, leaving behind dry solids that can be disposed of or used as a valuable byproduct. The remaining clean water can be reused within the facility for purposes like cooling, cleaning, or irrigation.

Get in touch today to discuss Zero Liquid Discharge System for your Plant

Benefits of Zero Liquid Discharge System

There are numerous benefits to implementing a zero liquid discharge system within an industrial facility. Some of the most significant benefits include:

Conserves water resources by recycling wastewater: Zero Liquid Discharge System recycles and reuses wastewater, which reduces the amount of freshwater needed for industrial processes. This helps conserve water resources and promotes sustainable water management practices.

Improves compliance with environmental regulations: By implementing Zero Liquid Discharge System, companies can comply with environmental regulations related to wastewater management and discharge. This enhances their reputation and demonstrates their commitment to environmental responsibility.

Reduces the risk of fines and penalties for non-compliance: By complying with environmental regulations, companies can avoid the risk of fines and penalties associated with non-compliance. This reduces financial liabilities and strengthens their sustainability profile.

Minimises environmental impact on water bodies and ecosystems: Zero Liquid Discharge System reduces the impact of industrial activities on nearby water bodies and ecosystems by reducing the discharge of pollutants and contaminants. This promotes sustainable industrial practices and reduces negative impacts on the environment.

Enhances sustainability profile and reputation: Adopting ZLD system enhances the sustainability profile and reputation of companies. This helps attract customers and investors who value sustainable practices and environmental responsibility.

Reduces off-site wastewater treatment and disposal needs: ZLD system eliminates the need for off-site wastewater treatment and disposal, reducing the costs associated with transportation and treatment. This promotes sustainable waste management practices.

Reduces operating costs of wastewater treatment and disposal: By reusing wastewater on-site, companies can reduce the costs associated with treating and disposing of wastewater. This leads to cost savings and promotes sustainable practices.

Increases efficiency of water usage and production processes: ZLD system increases the efficiency of water usage and production processes by reducing the amount of water needed for industrial processes. This helps conserve water resources and reduces water-related costs.

Minimises contamination risks from wastewater discharge: ZLD system minimizes the risks of contamination from wastewater discharge, which can harm human health and the environment. This promotes sustainable industrial practices and reduces negative impacts on the environment.

Reduces risks of accidents and spills associated with wastewater: ZLD eliminates the need for off-site wastewater storage and transportation, reducing the risk of accidents and spills. This promotes workplace safety and sustainable waste management practices.

Enhances corporate social responsibility and community relations: Adopting ZLD technology in India enhances corporate social responsibility and community relations by demonstrating a commitment to sustainable practices and environmental responsibility. This fosters positive relationships with stakeholders and communities.

Recovers valuable resources from wastewater for reuse or sale: ZLD technology in India can recover valuable resources from wastewater, such as minerals and salts, which can be reused on-site or sold for profit. This promotes resource efficiency and sustainable practices.

Increases overall profitability by reducing water usage and disposal costs: By reducing water usage and minimizing disposal costs, ZLD can increase the overall profitability of companies. This promotes sustainable business practices and enhances financial performance.

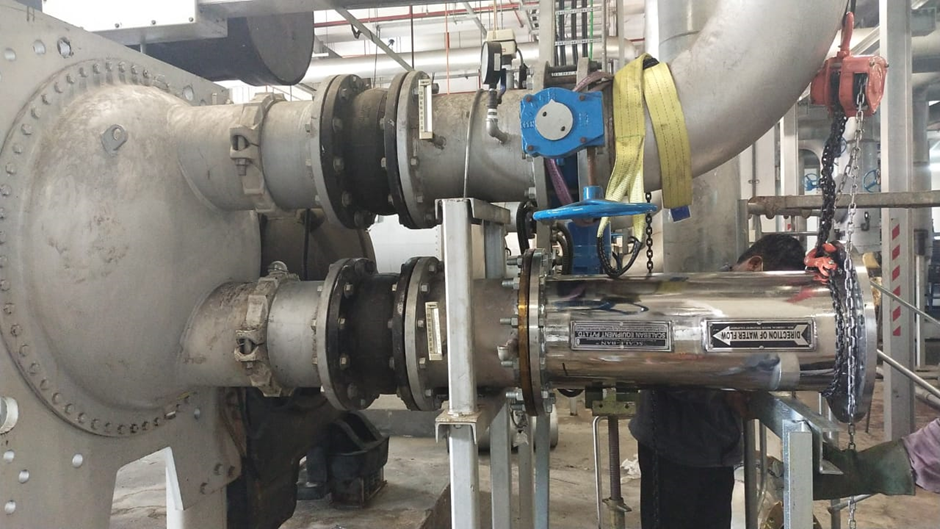

ZLD by SCALEBAN Equipments Pvt. Ltd. is the world’s only company providing a unique, disruptive, and sustainable technology for Water Treatment Plant and Zero Liquid Discharge (ZLD) objectives globally i.e. without wastewater RO and Evaporator (MEE) which consume a high amount of power and steam to operate resulting in high CO2 emission which is again a global concern, with Scaleban technology, industries can utilize ETP treated water as makeup to cooling tower and can achieve 15-20 COC against conventional ways where cooling towers maintain 5-6 COC max. despite using Soft and RO water in cooling towers. Higher COC leads to negligible blowdown hence reducing the load on ETP too.

Get in touch today to discuss Zero Liquid Discharge System for your Plant

Applications of Zero Liquid Discharge System

Zero liquid discharge system can be used in a wide range of industrial applications, including:

Oil & Gas Plants: The oil and gas industry generates large volumes of wastewater during the production, refining, and processing of crude oil and natural gas. This wastewater contains high levels of contaminants, including heavy metals, organic compounds, and salts. By implementing the ZLD system, these contaminants can be removed from the wastewater and the water can be reused or safely discharged into the environment. ZLD not only reduces the industry’s environmental footprint but also helps to conserve precious freshwater resources.

Chemical Plants: Chemical manufacturing plants produce a wide range of chemicals, including acids, alkalis, solvents, and other hazardous substances. These plants generate large volumes of wastewater that contain high levels of pollutants, including heavy metals, solvents, and acids. ZLD is often used in chemical manufacturing to treat this wastewater and remove these pollutants, ensuring that they do not harm the environment or public health. ZLD also helps chemical manufacturers comply with environmental regulations and reduce their operating costs by recovering valuable resources from wastewater.

Power plants: Power plants generate electricity by burning fossil fuels such as coal, oil, and natural gas. This process produces large volumes of wastewater that contain high levels of dissolved solids, metals, and other pollutants. ZLD can be used to treat this wastewater and remove these pollutants, ensuring that they do not contaminate nearby waterways or harm local ecosystems. In addition, ZLD can help power plants reduce their water usage and improve their overall environmental performance.

Pharmaceutical Plants: Pharmaceutical manufacturing plants produce a wide range of drugs and other products. These plants generate large volumes of wastewater that contain high levels of pharmaceuticals and other organic compounds. ZLD can be used to treat this wastewater and remove these compounds, ensuring that they do not enter the environment and pose a risk to public health. ZLD also helps pharmaceutical manufacturers comply with environmental regulations and reduce their operating costs by recovering valuable resources from wastewater.

Petrochemicals Plants: Petrochemical plants produce a variety of chemicals and products from petroleum, including plastics, solvents, and other chemicals. These plants generate large volumes of wastewater that contain high levels of pollutants, including heavy metals and organic compounds. ZLD can be used to treat this wastewater and remove these pollutants, ensuring that they do not harm the environment or public health. By implementing ZLD, petrochemical manufacturers can also reduce their water usage and improve their overall environmental performance.

Textile Plants: Textile manufacturing plants produce clothing, fabrics, and other textile products. These plants generate large volumes of wastewater that contain high levels of dyes, solvents, and other pollutants. ZLD can be used to treat this wastewater and remove these pollutants, ensuring that they do not harm the environment or public health. ZLD also helps textile manufacturers comply with environmental regulations and reduce their operating costs by recovering valuable resources from wastewater.

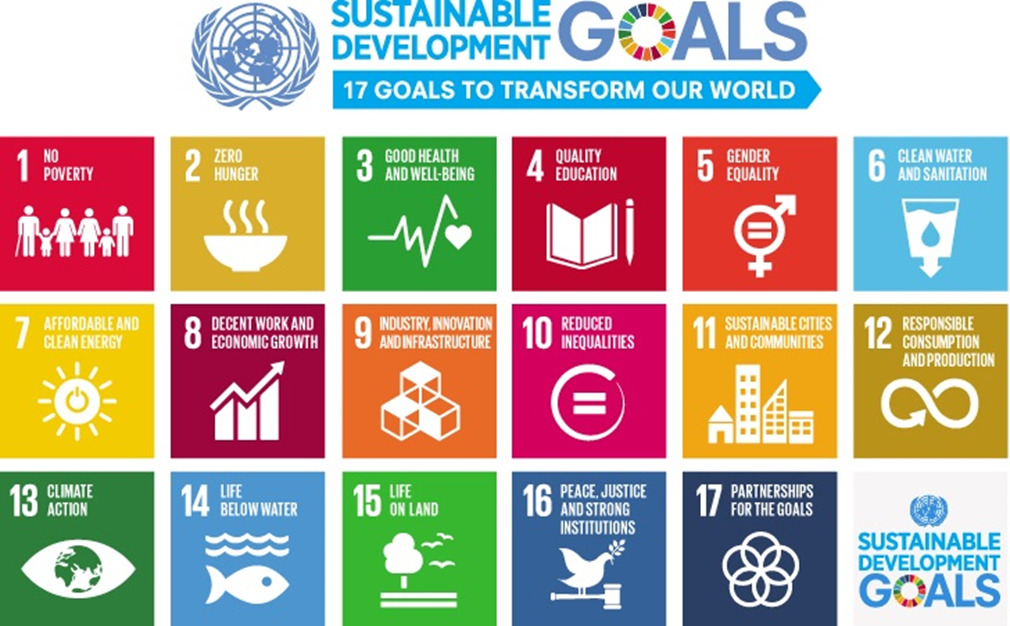

ACHIEVE UNITED NATION SUSTAINABLE DEVELOPMENT GOAL

Goal 6: Clean Water and Sanitation

This goal aims to ensure the availability and sustainable management of water and sanitation for all. Access to clean water and sanitation is essential for the health and well-being of individuals and communities, as well as for the sustainable use of water resources. To achieve this goal, efforts are focused on improving water quality, increasing water-use efficiency, and promoting sustainable water management practices. One of the key strategies to achieve this goal is to implement technologies such as Zero Liquid Discharge system that help to treat wastewater and reduce water pollution.

Goal 7: Affordable and Clean Energy

This goal aims to ensure access to affordable, reliable, sustainable, and modern energy for all. The transition to clean energy sources, such as solar, wind, and hydropower, is essential to reducing greenhouse gas emissions and addressing climate change. ZLD technologies can also play a role in achieving this goal by reducing the energy consumption of water treatment processes and promoting energy-efficient practices in industrial processes.

Goal 13: Climate Action

This goal aims to take urgent action to combat climate change and its impacts. The use of fossil fuels is a major contributor to climate change, and the transition to clean energy sources is critical to addressing this issue. In addition, reducing the release of pollutants and greenhouse gases into the environment, including through the use of ZLD, can help to mitigate the impacts of climate change.

Goal 14: Life Below Water

This goal aims to conserve and sustainably use the oceans, seas, and marine resources for sustainable development. One of the key issues facing our oceans is water pollution, which can harm marine ecosystems and the species that depend on them. Implementing ZLD technologies in industrial processes can help to reduce water pollution and protect marine environments. Additionally, promoting sustainable fishing practices and reducing marine litter can also contribute to achieving this goal.

ZLD technology can help achieve UN sustainability goal no. 06, 07, 13, & 14 by treating and reusing wastewater within a facility, eliminating all liquid discharge. This water treatment process reduces the water footprint of a facility, protects and conserves water resources, and contributes to other sustainability goals. ZLD is the future of wastewater management.

ZLD is an effective way to reduce the water footprint of a facility, as it minimizes the need for freshwater intake and wastewater discharge. This is important in areas where water is scarce or where wastewater treatment infrastructure is lacking. By reducing water consumption and wastewater discharge, ZLD can help you in the best way to protect and conserve water resources, while also reducing pollution and environmental impacts.

To sum up, the Zero Liquid Discharge system has brought about significant progress in managing industrial wastewater. The ZLD system is an eco-friendly and productive solution that eliminates the discharge of liquid waste while recovering precious resources like water and salt. As various industries face mounting pressure to reduce their ecological footprint and comply with regulations, the ZLD system offers an essential tool to address these challenges. Hence, it is expected that the ZLD system will become more prevalent in industrial settings worldwide. Get in touch with Scaleban Equipment for achieving water conservation.