Water scarcity is a critical global challenge, exacerbated by population growth, industrialization, and climate change. As freshwater resources become increasingly strained, the need for efficient and sustainable water treatment solutions has never been more urgent. In recent years, the ZLD approach has emerged as a revolutionary solution, transforming the global water treatment sector.

About ZLD System in India

Zero Liquid Discharge is an innovative process to eliminate liquid waste discharge from industrial and municipal facilities. Instead of releasing treated wastewater into rivers or oceans, ZLD systems in India recover and reuse virtually all water, while converting residual waste into valuable byproducts. This paradigm shift in water management has gained significant traction due to its economic, environmental, and regulatory benefits.

How is ZLD System in India transforming the Global Water Treatment Sector?

The Zero Liquid Discharge approach revolutionizes the global water treatment sector by alleviating water scarcity and promoting resource conservation. These systems maximize water recovery, reducing dependence on freshwater sources and enabling sustainable operation in water-stressed regions. Reusing recovered water within industrial processes, It reduces the need for freshwater intake, saving water and reducing energy consumption. The byproducts generated during the process can be further processed and utilized, minimizing waste generation and maximizing resource utilization, aligning with circular economy principles. Moreover, it eliminates wastewater discharge, preventing pollution of natural water bodies and safeguarding aquatic ecosystems and public health. It also contributes to combating climate change by reducing carbon emissions through energy-efficient design and advanced technologies. This technology aligns with evolving regulatory frameworks that impose stringent effluent discharge standards, enabling industries to comply while achieving operational efficiency and avoiding fines or shutdowns. Technological advancements in membrane filtration, evaporation, and automation have enhanced the performance and scalability of ZLD systems in India, making them economically viable for various sectors.

Get in touch with us today to discuss Zero Liquid Discharge

How Scaleban Helps You in Achieving ZLD

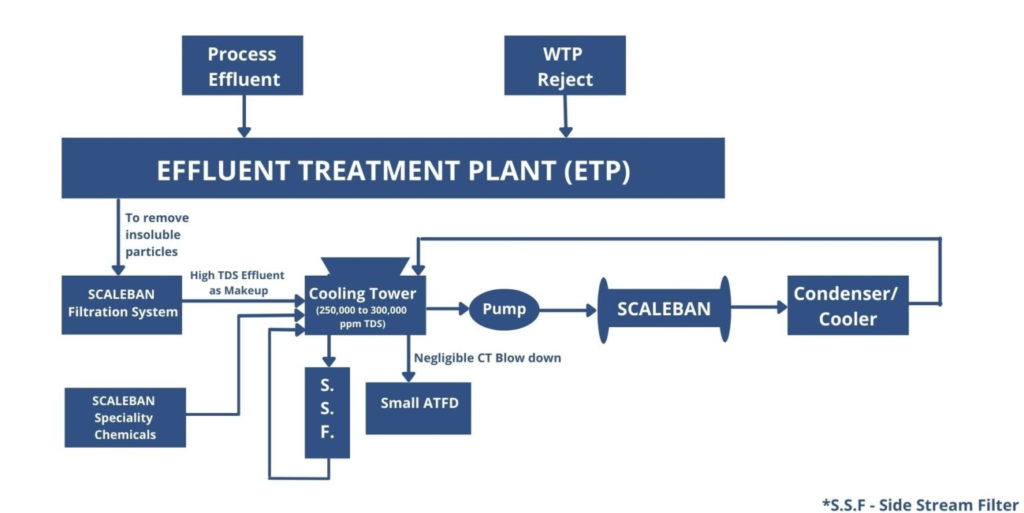

Scaleban technology offers an effective solution for achieving water conservation and Zero Liquid Discharge in industries by utilizing treated wastewater as makeup to cooling towers eliminating fresh water requirements while ensuring zero scales, corrosion, and biofouling. This technology also enables the high concentration of dissolved solids, with Total Dissolved Solids (TDS) ranging from 25% to 30%, in the cooling tower circuit. High TDS operation allows negligible blowdown from cooling towers, which can be directly used in ash quenching hence eliminating the requirement of wastewater RO and MEE.

The Scaleban system comprises three key components: the “SCALEBAN” equipment, “SCALEBAN” Specialty Chemicals, and a glass media-based filtration system. By integrating these elements, Scaleban technology can efficiently handle wastewater with high TDS levels.

The primary aim of Scaleban technology is to eradicate the occurrence of scale, corrosion, and biofouling completely within the cooling tower circuit. Scale pertains to the buildup of mineral deposits on surfaces involved in heat transfer, impairing efficiency and raising energy consumption levels. Corrosion can cause damage to equipment and piping systems, leading to leaks and breakdowns.

Scaleban technology ensures optimal performance and prolongs the operational lifespan of cooling tower systems by successfully mitigating scale formation, corrosion, and biofouling. Additionally, the use of wastewater in cooling towers significantly reduces freshwater intake, contributing to water conservation efforts and promoting sustainable water management practices.

Scaleban Technology Advantages

- 80% saving in CAPEX.

- 80% saving in OPEX.

- Very easy to establish the results.

- No maintenance/replacement of parts is required for 20 years.

- Zero Footprints is an online equipment.

- It can handle variable water qualities in cooling towers.

- Reduction in CO2 emissions.

- Return on Investment (ROI) within 12-18 months.

- Supply installation and commissioning time within 6-8 weeks.

Get in touch with us today to discuss Zero Liquid Discharge

About United Nations Sustainable Development Goals

In the context of Zero Liquid Discharge in India, an innovative water treatment solution, several United Nations Sustainable Development Goals (SDGs) are closely aligned. SDG 6 focuses on clean water and sanitation, SDG 7 emphasizes affordable and clean energy, and SDG 14 highlights the conservation and sustainable use of marine resources. ZLD in India plays a significant role in addressing these goals and promoting sustainable development.

SDG 6 aims to ensure access to clean water and sanitation for all. ZLD technology in India contributes to this goal by treating wastewater and minimizing its impact on water resources. ZLD systems effectively remove contaminants, pollutants, and harmful chemicals, producing high-quality water suitable for various purposes, including drinking water. By implementing this technology, communities can have access to safe and clean water, reducing waterborne diseases and improving overall health and well-being.

SDG 7 targets affordable and clean energy. This system incorporates energy-efficient technologies, such as advanced filtration processes and innovative treatment methods, minimizing energy consumption during the water treatment process. By optimizing energy usage, Zero Liquid Discharge in India promotes sustainable practices and helps reduce the carbon footprint associated with water treatment solutions in India.

SDG 14 focuses on the conservation and sustainable use of marine resources. ZLD plays a crucial role in preventing marine pollution by treating industrial wastewater and eliminating the discharge of harmful chemicals and pollutants into rivers, lakes, and oceans. By implementing ZLD, industries can significantly reduce their impact on marine ecosystems, preserving biodiversity and safeguarding the delicate balance of marine resources.

In conclusion, this approach is revolutionizing the global water treatment sector by offering a sustainable and efficient solution to water scarcity and pollution. Its ability to recover and reuse nearly all water while converting waste into valuable resources aligns with the principles of resource conservation and circular economy. Moreover, Zero Liquid Discharge in India helps industries comply with increasingly stringent regulatory standards, avoiding penalties and ensuring long-term sustainability. As technological advancements continue to drive down costs and improve performance, the widespread adoption of ZLD is poised to transform the global water treatment sector and pave the way for a more sustainable and water-resilient future.