Background of Aditya Birla Chemicals (ABCTL),Thailand

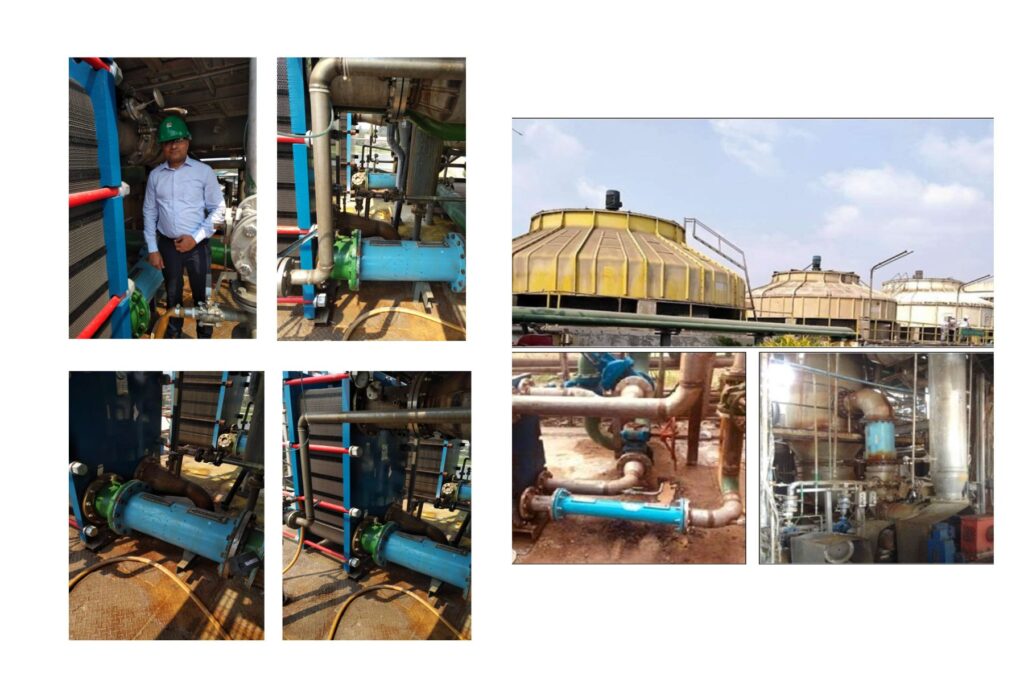

Aditya Birla Chemicals (Thailand) (ABCTL) is a part of the Aditya Birla Group’s chemicals business. Aditya Birla Chemicals (Thailand), Sulphites Division located at Saraburi, Thailand and manufacturing Sodium Sulphites and Sodium Meta-Sulphites products.

Challenges for ABCTL

ABCTL is generating 250 m3/day Process wastewater having TDS of 20,000 ppm. As per Thai Pollution Control Board norms, ABCTL had to recycle this effluent for reuse and to achieve Zero Liquid Discharge (ZLD). Quality of this effluent was not suitable for RO hence they had no other option but to install Multi Effect Evaporator (MEE) for achieving ZLD objective. High CAPEX & OPEX was the serious concern for them to treat 250 m3/day process wastewater through Evaporator (MEE)

“SCALEBAN” Solution

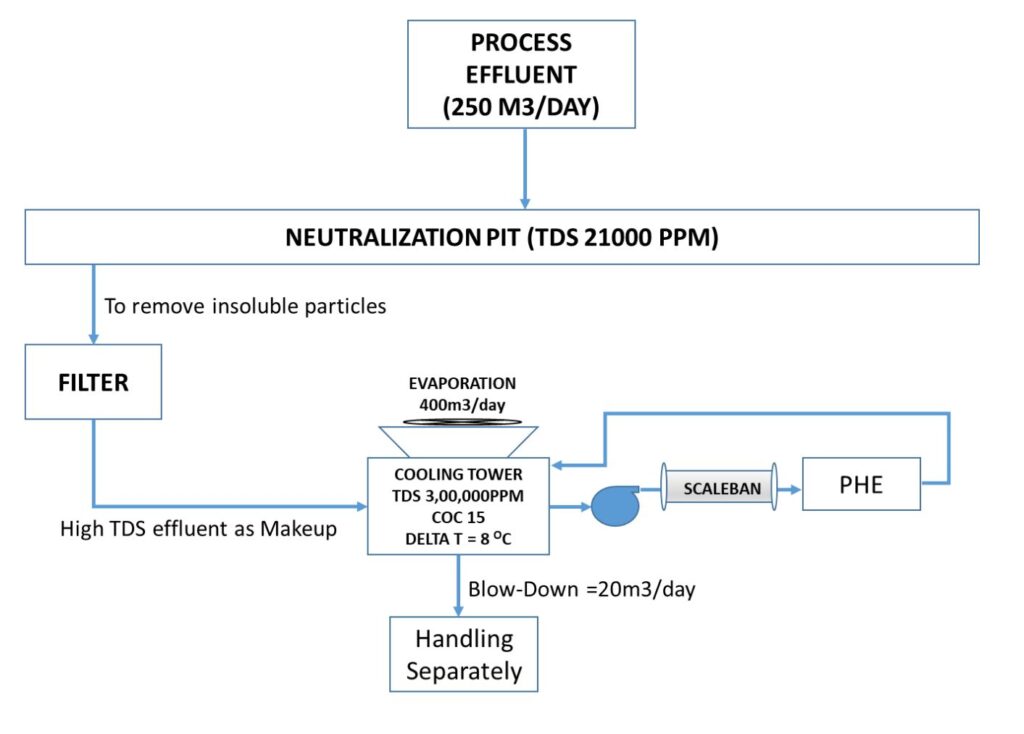

ABCTL installed 27 nos. of “SCALEBAN” equipment at the cooling water inlet of different process plant heat exchangers in Feb 2019 to utilize 250 M3/Day process effluent (Waste Water) as makeup in place of fresh water at their main process plant cooling tower. After implementation of “SCALEBAN” Equipment at the inlet of 27 nos. process heat exchangers (PHEs) and by using “SCALEBAN” Specialty chemicals in cooling towers, ABCTL is successfully using wastewater in their process plant cooling tower and operating it at 3,00,000 PPM TDS(30%). Due to high COC operation of cooling tower ABCTL is giving only 20 m3/day blowdown having 30% TDS which they are sending to authorized agency in Thailand to handle it separately. ABCTL could manage to achieve ZLD objective on a sustainable & most cost-effective basis by installing “SCALEBAN” technology without implementing costly conventional evaporation (MEE) technology.

ABCTL observed smooth operations of the plant with respect to heat exchange coefficient due to zero scaling in heat exchangers even at such high TDS level besides saving 250M3/Day fresh water. ABCTL also observe corrosion and biofouling free operation of the entire cooling tower circuit.

Achievements of the “SCALEBAN” Project

- Achieved water conservation and ZLD objectives on a sustainable basis.

- Saving in high CAPEX of MEE (Evaporator).

- Saving in high OPEX of MEE (Evaporator).

- 100% saving of fresh water consumption in cooling towers.

- Completed project in 6-8 weeks.

Considerable reduction in Carbon footprint.

High COC operations of the cooling tower. - Substantial reduction in cooling tower blowdown quantity.

- Zero scale, corrosion & biofouling free operation of the condensers/coolers

- By implementing Scaleban technology ADITYA BIRLA contributed in

achieving UN sustainable development goal no. 6,7,13,14

After successful operation of the “SCALEBAN” project, ABCTL awarded repeat order to “SCALEBAN” for their another facility in Thailand. “SCALEBAN” Technology is handling 300m3/day process waste water and other cooling tower blowdown in process plant cooling tower successfully and achieving their water conservation and ZLD objectives on a sustainable basis.

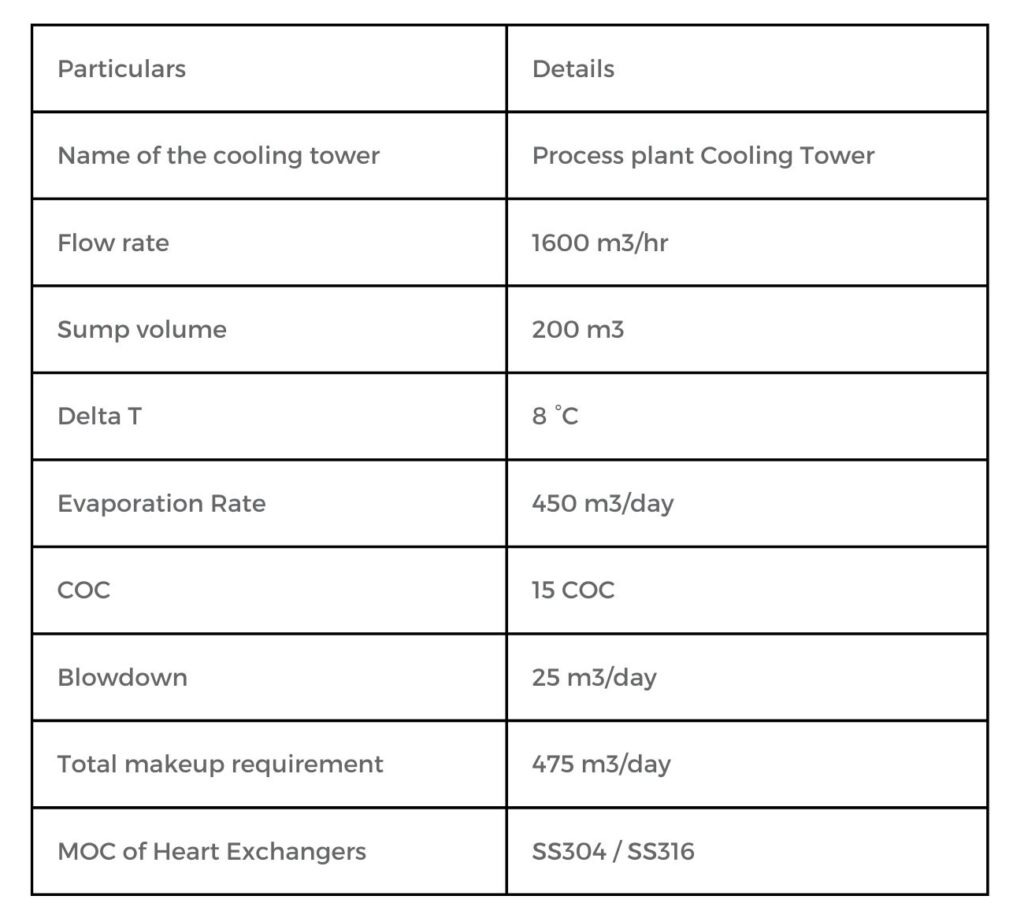

Details of Process plant Cooling Tower

Parameters of wastewater (Makeup) & cooling tower Re-circulation water

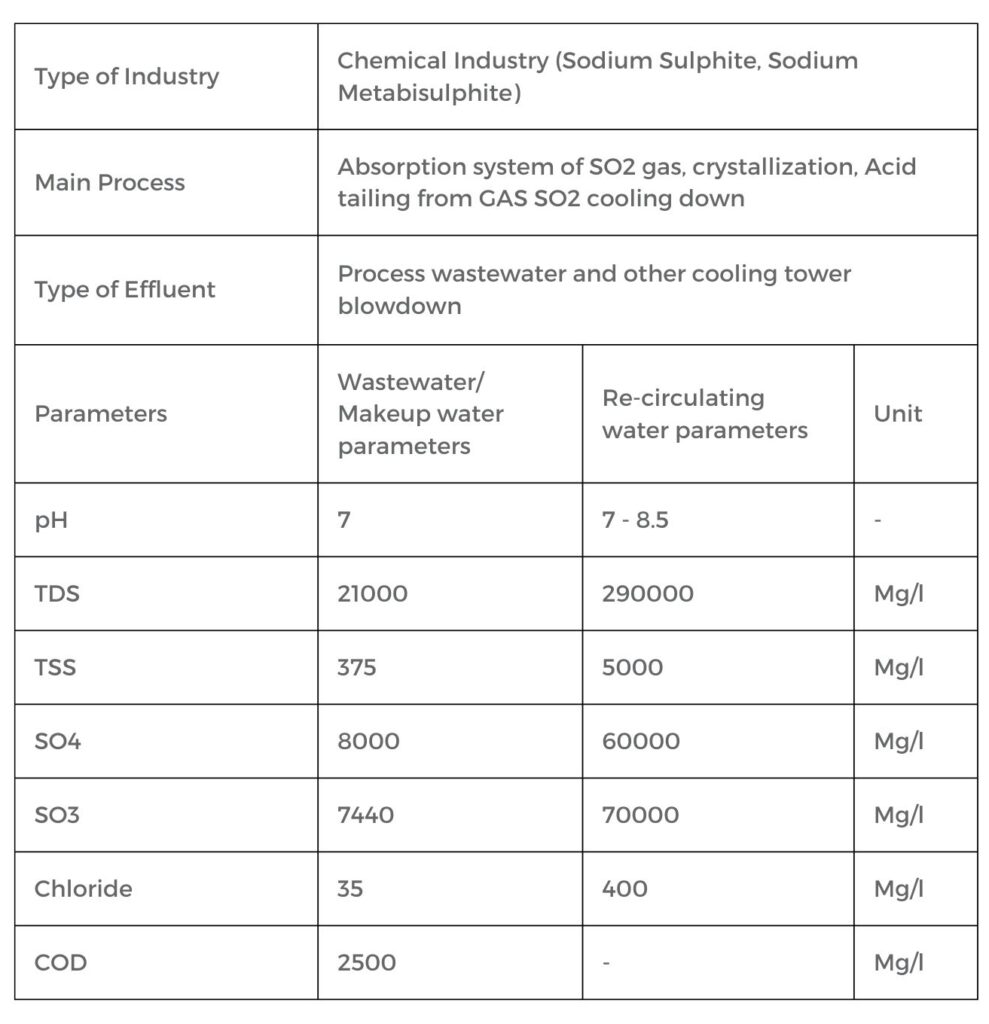

“SCALEBAN” ZLD SCHEME

"SCALEBAN" Installation

Appreciation of "SCALEBAN" technology at ABCTL, Thailand:

We are thankful to ABCTL, Thailand for implementing “SCALEBAN” Technology for achieving water conservation and ZLD objectives on a Sustainable basis.